Table of Contents

Speed Density - Vacuum Hose Considerations

In testing various speed density installations, we've noticed that the vacuum hose configuration leading from the manifold to the pressure sensor can be an important consideration in getting throttle response right.

Worst Case

The worst case scenario is to have a vacuum hose coming off the manifold into a small tee and then off through a long length of additional vacuum hose leading to the pressure sensor. The tee can act as a restriction leading to additional delay in equalizing the pressure between the manifold and pressure sensor. That delay can wreak havoc on throttle response and can even cause the engine to have trouble starting or idling properly.

Best Case

The “best case” scenario is to locate the pressure sensor directly on the manifold.

2G DSM Example

An example is shown below on a 2G using an MDP adapter from Road Race Engineering and an AEM 5-bar sensor (click image to enlarge).

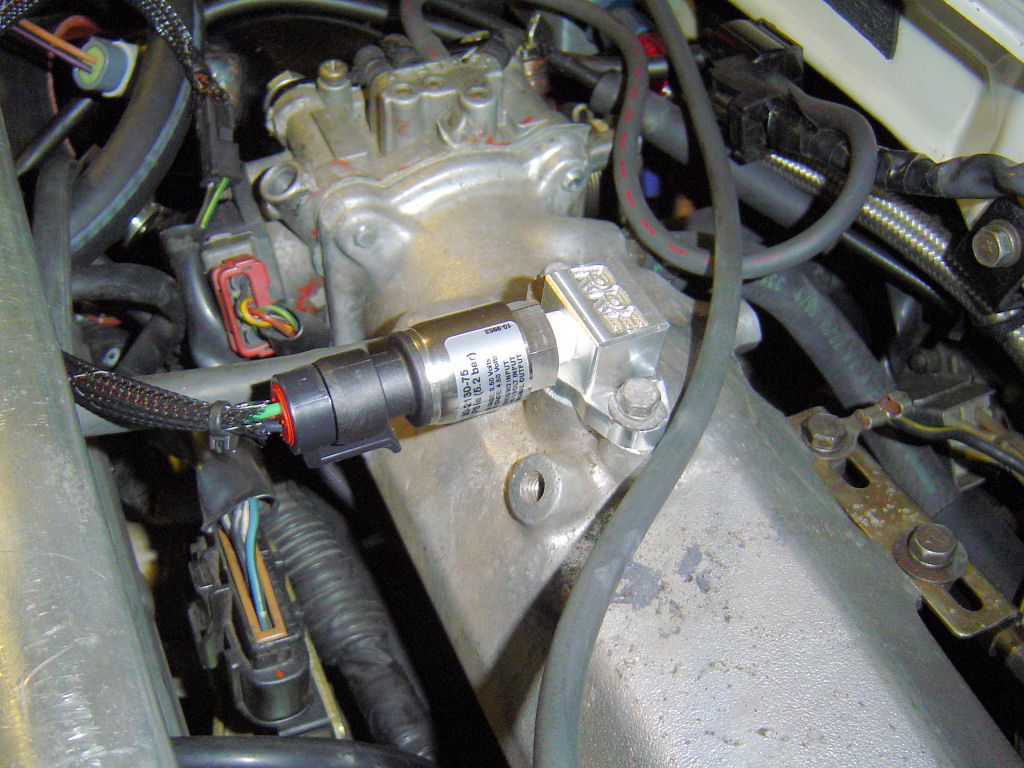

1G DSM Example

For a 1g intake manifold, you can drill and tap (1/8“ NPT) the boss next to the brake booster nipple and thread the sensor in with teflon tape on the threads. An example is shown below with an AEM 5-bar sensor (click image to enlarge).

Middle Ground

It's not always possible to run a pressure sensor directly off the manifold. So a reasonable “middle” ground seems to be a single vacuum hose about 6-8 inches in length with no tees running straight from the manifold to the pressure sensor. This allows the pressure sensor to be mounted to the firewall, for example, with a simple vacuum hose running straight from it to the manifold.